It’s Simple.

Safety: First. Last. Always.

This commitment begins with the philosophy of “Safety First” in everything we do. We mean it when we say, “Safety: First. Last. Always!”. We are dedicated to centering each construction phase on resident, staff, visitor, and employee safety. Safety guides our processes, planning, and approach to each project.

Our most important asset is our people. We consider every individual in our offices and on a job site our company’s responsibility. Employee safety not only affects what happens on the job; it also affects the personal lives of our workers and the people they love.

Recognition

Though we are honored to be repeat winners of numerous safety awards, safety is a corporate culture that must be promoted constantly.

2023 ASSOCIATED BUILDERS AND CONTRACTORS (ABC) SAFETY MANAGEMENT SYSTEM (STEP) AWARD

STEP Diamond

2022 KCA H.B. ALEXANDER TROPHY

Safest record with zero injuries over 100,000 hours

2022 ASSOCIATED BUILDERS AND CONTRACTORS (ABC) SAFETY MANAGEMENT SYSTEM (STEP) AWARD

STEP Diamond

2022 ABC KEYSTONE EXCELLENCE IN CONSTRUCTION SAFETY

Zero OSHA citations for 2021. 100% commitment to safety at all times.

2021 ABC STEP Award

STEP Diamond

2020 PBX - Pennsylvania Builders Exchange - Safety Excellence Award

Over 150,000 hours

2020 Keystone Contractors Association (KCA) Safety Award

Zero Lost Time

2020 ABC STEP Award

STEP Platinum

2019 KCA H.B. Alexander Trophy

Safest record with zero injuries over 100,000 hours

2019 ABC STEP Award

STEP Platinum

2018 PBX Pennsylvania Builders Exchange Safety Excellence Award

Over 150,000 Hours

2018 Millennium Captive Insurance Co., Ltd.

Lost Workday Case Rate, Total OSHA Recordable Rate, and DART Rate Below the Industry Average for NAICS Code 236220

2018 Millennium Captive Insurance Co., Ltd Outstanding safety performance

861.3 Awards Program Points

2018 KCA H.B. Alexander Trophy

Safest record with zero injuries over 100,000 hours

Safety is our culture.

There is no other way

Our safety program is integrated into our culture and on our job sites through training, education, and going beyond industry standards. We make an industry-wide effort to train our colleagues to prevent any worker in the industry from suffering an injury. We provide on-site training for various hazards that workers may encounter, including job safety analysis, OSHA 10- and 30-hour training for construction and general industry (500 & 501), and even confined space, excavation, fall protection, and equipment operating training. We are vigilant in inviting OSHA consultants and private safety consultants to survey our safety program and provide feedback to keep every single site an injury-free zone.

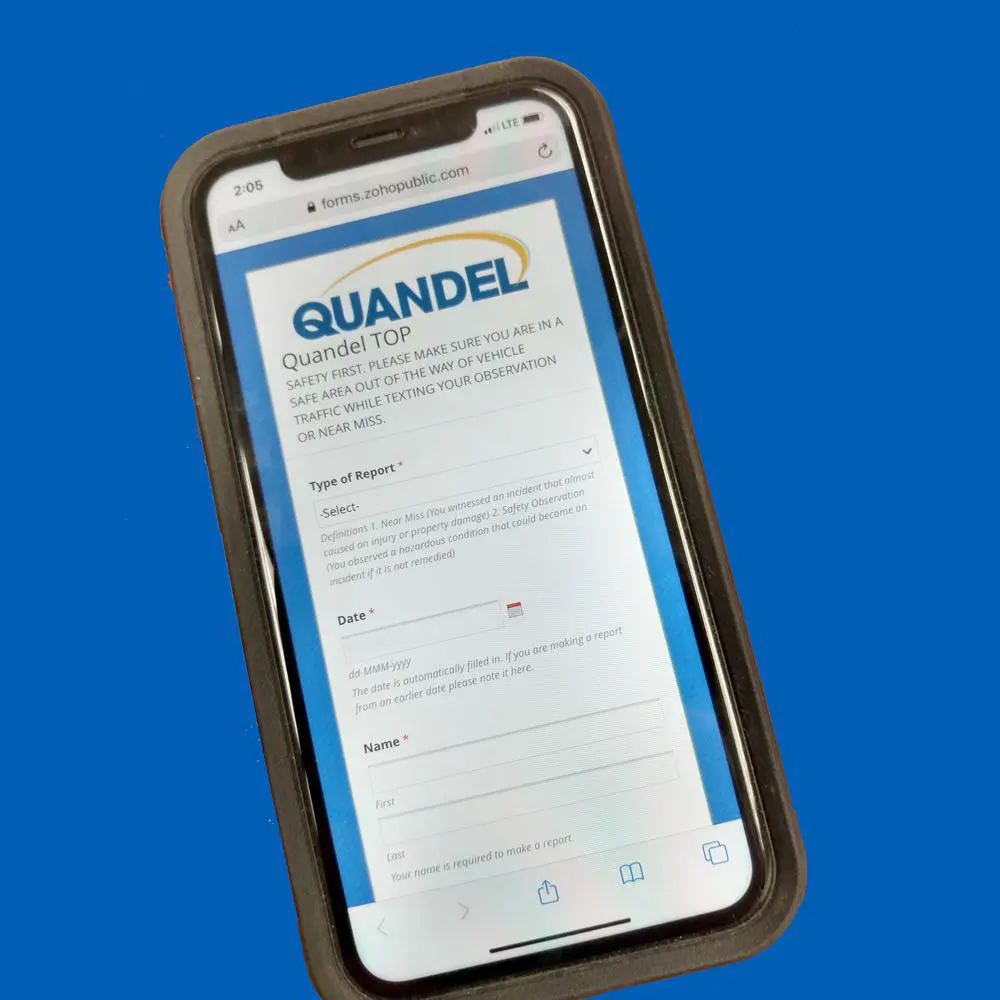

Our construction team personnel are certified in First Aid, CPR, AED, and OSHA 10-hour at a minimum. Each year, our team members complete additional safety training to enhance their knowledge of project-specific challenges. We also have a Text Observation Process (TOP) program used for superintendents and project managers to report Safety Observations easily and Near Misses and corrective actions in real-time from an app on their phones. Safety Talks are presented every week and shared with subcontractors. We also have a subcontractor prequalification process to review subcontractors’ safety process and financials. We believe in the importance of regular safety inspections and weekly jobsite inspections. Year after year, we maintain our EMR rating well below the industry average of 1.00.

Safety Guides the

Process. Always.

At Quandel, our standards are guided by our core values that define our commitment to providing a safe work environment supported by policies that meet or exceed federal, state, and local laws. We are constantly thinking about ways to work safely. We define success in safety when every employee on every project site can return home to their families safely.

How do we commit?

Safety Talks

Safety is not merely an item on a checklist. It is a commitment and a necessity that we have carved into our building philosophy and it guides the processes, planning and approach to all of our projects.