Lifting and rigging tasks are considered high-hazard tasks by many companies. There are a lot of associated hazards that accompany lifting any loads with cranes or equipment. It is important to not only understand proper rigging techniques but also the other hazards that accompany this type of work task.

Lifting and rigging incidents can result in severe consequences, such as the breakage of a sling, wire rope, or chain resulting in a dropped load. However, there are often many other types of less severe incidents that cause many injuries or property damage. Hazards such as swinging loads, manual handling of heavy rigging, holding on to tag lines, moving equipment, pinch points, working on elevated surfaces, trip hazards, slippery surfaces, etc., can be present during lifting operations.

Lifting and rigging safety practices must be followed to prevent incidents and injuries.

- Proper training: Anyone in a work area where a lift is being performed should be properly trained on the work scope, hazards, and mitigations of the task.

- Lift plan: Have a written lift plan that identifies the desired rigging, angles of equipment, lifting capacities, etc., prior to the start of the lift. Lifting plans shall be submitted and reviewed by Quandel Safety.

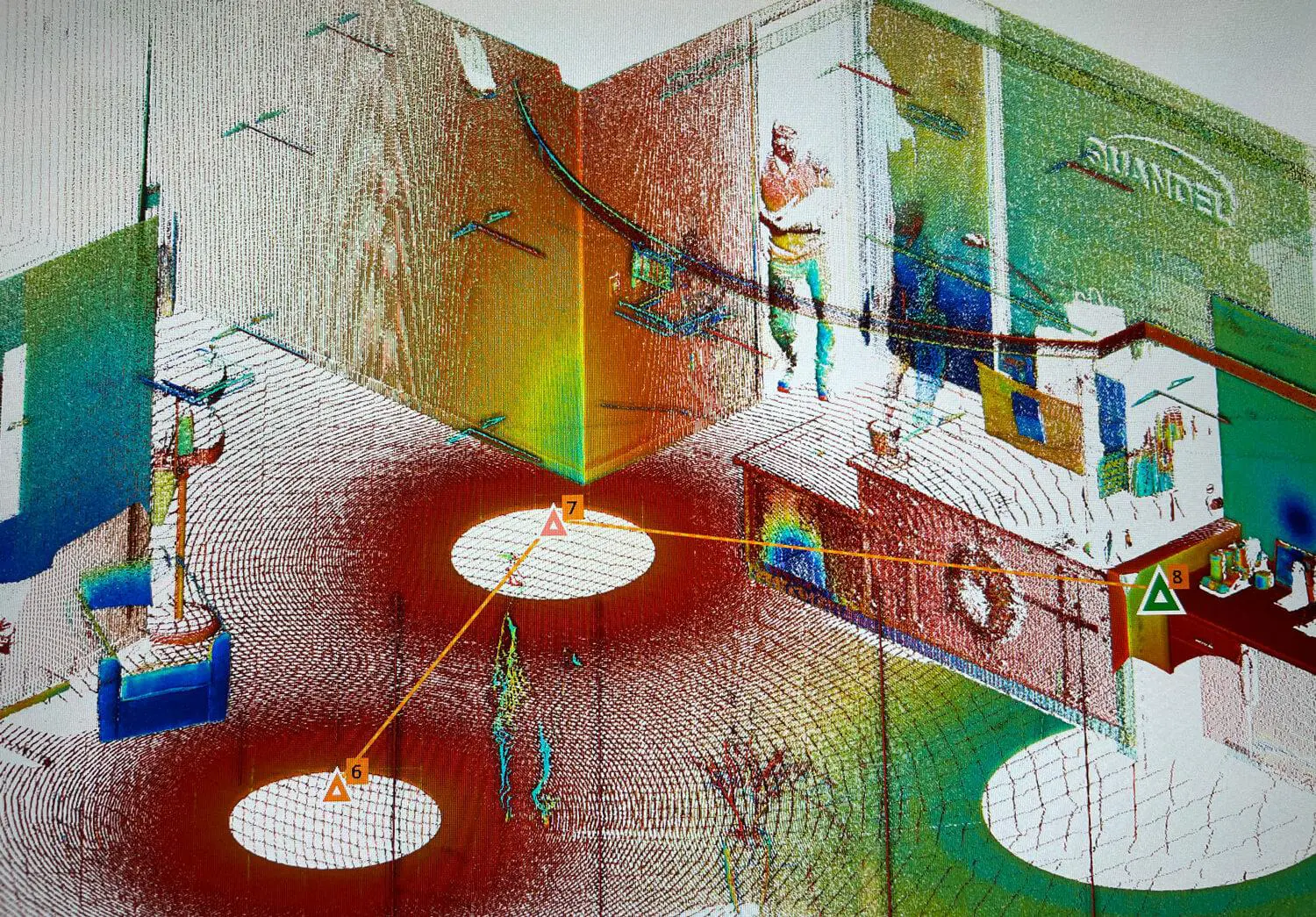

- Plan the travel area: Plan the travel area and potential lines of fire prior to the lift. This helps to avoid striking other objects or having to move objects or equipment after the load is already in the air.

- Inspect the rigging: Inspect all rigging prior to using it for a lift. Continuously check the integrity of the equipment throughout the day if there are multiple lifts. Remember that all slings MUST have a legible weight limit tag, or they are NOT to be used.

- Proper storage: All rigging should be properly stored after lifting operations are complete. Proper storage helps prevent the rigging from being damaged.

- Use a qualified rigger: A qualified rigger must be used to secure the load.

- Keep away from the load: Always use a tag line to ensure space from the load and ensure control of the load to keep it from swinging.

Regarding safety latches, hooks must be equipped with latches. Hooks without latches, or with latches removed or disabled, must not be used unless a qualified person has determined that it is safer to hoist and place the load without latches (or with the latches removed/tied back).

Routes for the loads are pre-planned to ensure that no employee is required to work in the fall zone except for employees necessary for the hooking or unhooking of the load.

This is not an exhaustive list of all the hazards and safe work practices when completing lifting and rigging activities. Proper planning is important to eliminate hazards and avoid incidents. Be aware of the hazards that affect you and your coworkers on each unique lift that is completed. Stay safe and follow the proper safety protocols when conducting lifting and rigging tasks.