Leading meat processor underway on the construction of innovative, comprehensive environmental management system

Following a devasting fire that burned its original facility to the ground in 2005, family-owned meat production company Nicholas Meat, LLC has rebuilt and grown to over 350 employees and 150 contract workers. The producer of USDA-inspected beef broke ground on its Sustainable Resource Facility (SRF) in the spring of 2021.

Fully funded by Nicholas Meat, the $50 million SRF will set a new standard for sustainability in the meat processing industry, bringing together award-winning waste-to-energy technology, advanced wastewater treatment, and water reclamation on an expansive 40 acres in Loganton, Pennsylvania’s Sugar Valley community. While the water reclamation and anaerobic digestive technology have been used as individual components of meat processing before, the innovative SRF integrates the processes to create a comprehensive, first-of-its-kind facility that will reduce Nicholas Meat’s carbon footprint while reusing 90 percent of its wastewater, minimizing dependence on land applications and generating green energy in biogas form.

“What’s unique about this particular facility is it brings many sustainable components and integrates them together into one system,” says Nicholas Meat’s Director of Sustainability, Brian Miller. “There’s the wastewater treatment side of it [and] there’s the anaerobic digestion, where we’ll be breaking down organic materials and generating biogas that we’ll use to power boilers that will heat the processed water that we use back in our beef processing operation. That’s one element of it, and then the wastewater treatment plant is actually going to enable us to reuse up to 90 percent of our water back into the facility.”

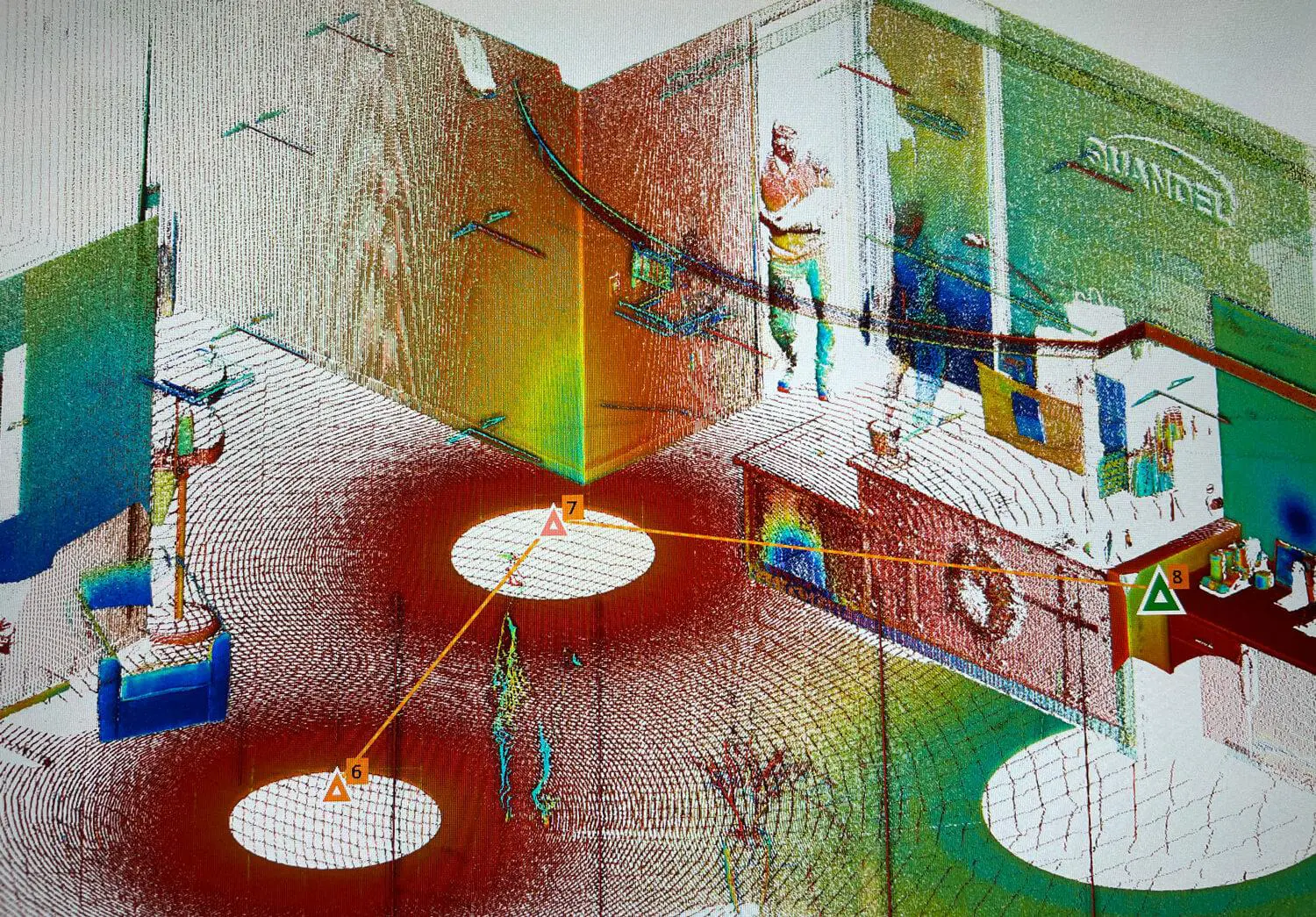

With decades of experience in the construction of water and wastewater treatment facilities, Harrisburg, Pennsylvania-based construction management firm Quandel Enterprises has been selected to oversee the development of the SRF. Milnes Engineering, the engineering division of Milnes Companies, will provide specialized civil, environmental, waste, and wastewater engineering support for the project.

System integration

The anaerobic digestion process, using microorganisms to break down solids such as food and cattle manure, will take place in two enclosed digesters adjacent to a newly constructed reception building. In this closed environment, the greenhouse gases and odors that are produced as a result of the process will be contained.

“The whole system from the onset was designed to minimize any odors that meat processing plants and other agricultural operations generate,” says Miller. “We felt it was very important, especially given the fact that we’re located right next to the small town of Loganton,. That was paramount in the design. In all the buildings, there’s a negative airflow, and all the room air will be exhausted out through an odor control device, so the whole site was designed keeping odor removal in mind.”

As a byproduct of the anaerobic process, biogas is captured and stored in the holding tank before being sent to power the boilers that are used to heat water for the plant. This will also eliminate the plant’s need for propane.

When the digestion process is completed, the nutrient-rich solid waste will be stored in a post digester before its eventual re-use as fertilizer on the farmland. The liquid waste will be sent to the SRF’s intertwined wastewater system for processing.

After the initial treatment in the wastewater system, which removes nitrogen and phosphorous, the water will be sent through a membrane bioreactor to filter out suspended solids. This permeate water can be used for less critical purposes such as washing down holding pens. Potable water, which is safe for food contact, goes through the reverse osmosis process for additional purification before being returned to the plant. When the new facility is fully operational, the reusable potable and non-potable water will minimize the demand on the underground aquifers that Nicholas Meat currently shares with nearby farmers and residents.

“It’s imperative that we do that [because] we’re kind of unique in the fact that we don’t have any access to a municipal water supply system, so all of the water that we use in our operations comes from the underground aquifers,” says Miller. “Obviously, other people depend on that aquifer—the residents of Sugar Valley [and] the other farmers in the area. We want to make sure that we put the processes in place that would ensure we have enough water but also to respect the rights of everybody else to use that water and that aquifer.”

Fostering preservation

The final component of the SRF project, the conservation reserve, will be situated on 12 acres in the 100-year floodway of Bald Eagle Creek. When the preserve is completed, the area will be home to some 2,500 trees, native wetland grasses, and other wildlife.

Upon completion of the SRF, Nicholas Meat will serve as stewards of sustainability for the entire Sugar Valley with significant environmental enhancements that will improve the company, the community, and the planet.

“Any time you can take waste streams that would have existed as a consequence of a process you’re doing [and] find a way to turn that into a renewable energy, that, to me, is the very definition of sustainability,” Miller says. “Any way that you can take the water you’re withdrawing from the aquifer and find a way to reuse a significant portion of that back into your operations, that’s the definition of sustainability.”

“Committed to leading, making a difference, and building a better future, Quandel is excited to partner with Nicholas Meat to make this happen for the community and the company,” said Mark Salak, Quandel Vice President and Project Executive. “A project of this magnitude shows the innovative economy and the commitment of sustainability in food processing and the construction industry,” Salak continued. “The SRF not only brings technology that will serve as a model throughout the meat processing industry, but it also demonstrates the role agriculture plays in building a strong economy in the United States.